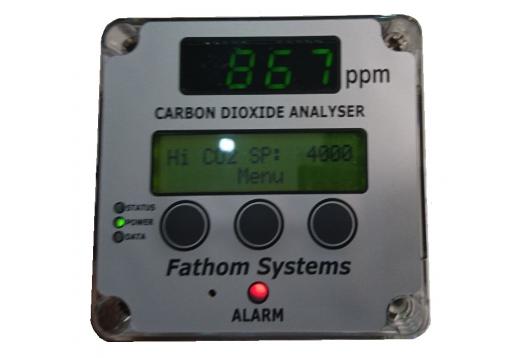

iGA – intelligent Gas Analysis

Highly accurate gas monitoring of oxygen, carbon dioxide and carbon monoxide content within chamber and diving bell breathing atmospheres.

With in-built audible voice alarm and automatic calibration, this range of products provides essential safety critical control and instrumentation for commercial diving operations.

READ MORE

Features:

- Oxygen concentration (pO2) – percentage concentration of standard atmospheric pressure.

- Carbon dioxide concentration (ppmCO2) – parts per million concentration of standard atmospheric pressure (10,000 ppm = 1%).

- Carbon monoxide concentration (ppmCO) – parts per million concentration of standard atmospheric pressure (0-50 ppm).

- Partial pressures – displayed in bars or millibars (mbar) as appropriate.

- Gas flowrate – displayed in millilitres per minute (ml/min).

- Depth – measured in metres of seawater (MSW).

- Pressure – measured in bars relative to 1-atmosphere (1 bar = 105 Pa).

- Time – measured in hours, minutes and seconds.

The necessity for the highest levels of safety in life support equipment is reflected in the manufacturing quality of these instruments and the design which incorporates a number of features that distinguish them:

- The high accuracy O2 , CO2 and CO analysers are accuracy compliant with DNV-OS-E402 to a maximum working depth of 300msw.

- The paramagnetic sensor used in the high accuracy O2 is not consumable doing away with the need to purchase, store, transport and manage replacement fuel cells.

- Analyser accuracy is optimised by maintaining constant gas flow, keeping the sensor at constant temperature and applying barometric compensation.

- Multi-coloured visual and spoken alarms.

- Analyser displays show percentage and partial pressure of oxygen, calculated by factoring in depth from a pressure sensor, existing depth data on the network or by manual input. Most analysers show surface equivalent (SE) %O2 values which do not reference chamber depth so alarm points must be calculated and then adjusted manually by the operator to compensate for depth change. Fathom Systems analysers do this automatically.

- Simple, semi-automatic software calibration procedures.

- Non-volatile storage of system settings and calibration data.

- Safety engine and dual watchdog technology is used in the O2 injection and depth monitor modules for safety integrity.

- Every module has comprehensive internal diagnostics that displays system status.

- Network connectivity.

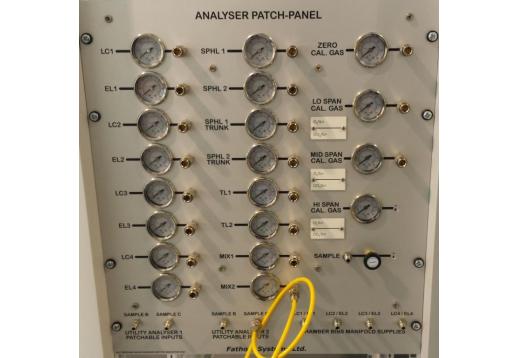

There are a number of possible options/ permutations for the analyser module configuration. These different configurations will depend on the desired installation functionality, and typical examples of installed modules are shown below:

- %O2 Master Analyser module (required).

- ppmCO2 Slave Analyser module (optional, but usually installed).

- ppmCO Slave Analyser module (optional).

- Sample Processor Module (4, 5 or 6 input type, with or without sample pump).

- O2 Injection Module (optional).

- ppO2 (fuel-cell sensor type) Slave Analyser Module (optional).

- 24V DC Power Supply (mounted within sub-rack or externally).